Sell sheet example page

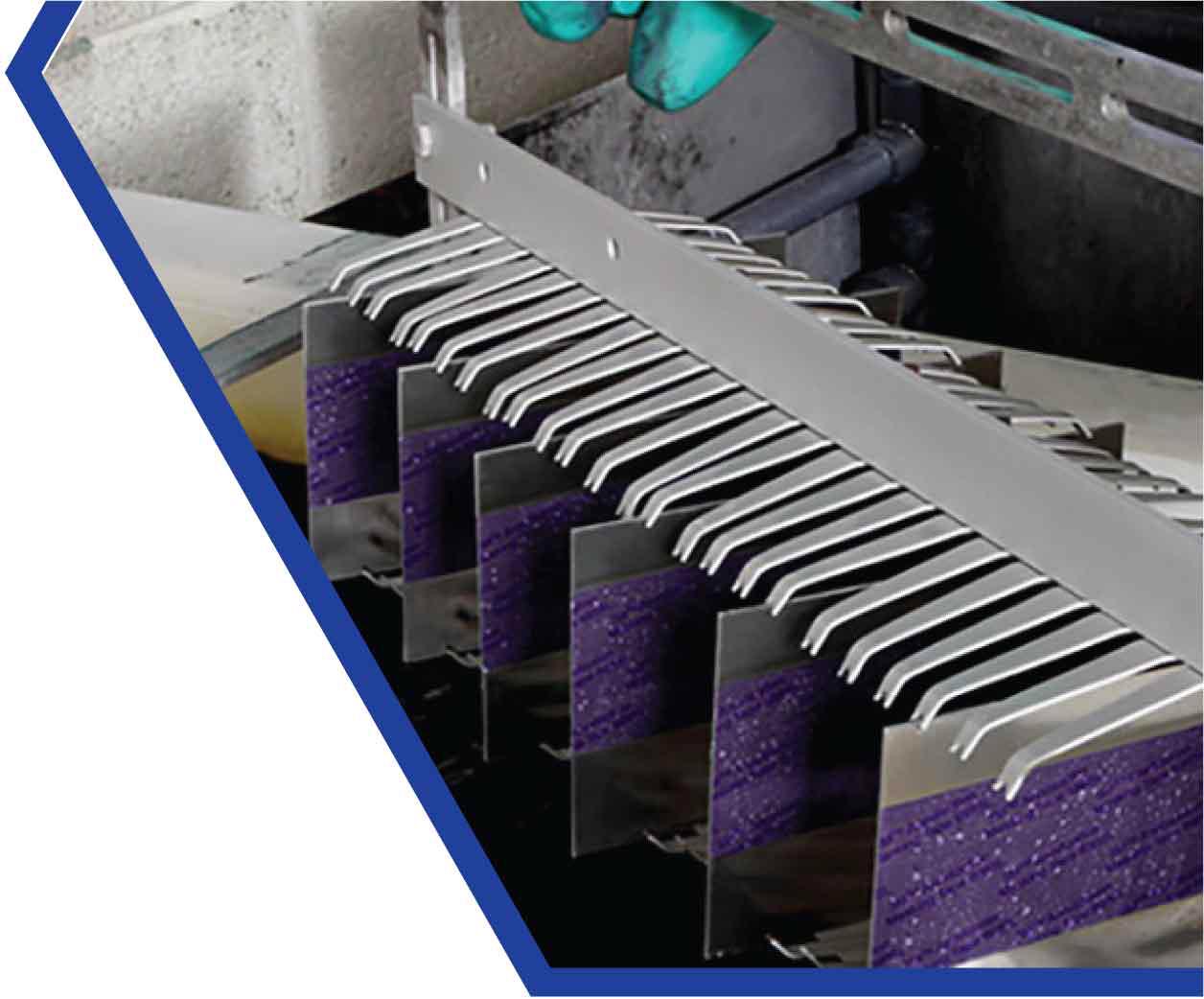

MASKING SOLUTIONS FOR SPECIALTY COATING APPLICATIONS

Electroplating, Anodizing, Hard Chrome PlatingMetal finishing is a complex process that involves chemicals, coatings, and harsh environments to strengthen of the metal by making it more durable and less prone to common element wear in its final product format. There are many types of metal finishing processes, but the most common are:

Electroplating is usually used to cover a less expensive metalwith a more expensive metal, or to cover a corrosive metal witha less corrosive or noncorrosive metal.Anodizing is a conversion coating process used to achieve anoxidized surface finish on metal components.It increases thethickness of the naturally occurring oxide layers on metal,enhancing the finished part's corrosion and wear resistance.Hard chrome plating is an electroplating process in whichchromium is deposited from a chromic acid solution. It is usedfor wear and corrosion resistance in addition to its low frictionand shiny characteristics. |

|

|

Thickness Series (mil) |

Backing |

Adhesive |

Adhesion (oz/in) |

Tensile Strength (lbs/in) Color |

Temp Resistance |

Key Features |

Finishing Process |

Common Applications |

||

|

|

||||||||||

|

3M 484 |

6.7 |

Vinyl |

Rubber |

22 |

23 |

Yellow Brown |

Up to 170°F |

|

|

|

|

3M 470 |

7.1 |

Vinyl |

Rubber |

37 |

20 |

Tan |

Up to 250°F |

|

|

|

|

3M 8985L |

3.9 |

Polyester |

Rubber |

20 |

70 |

Purple |

Up to 200°F |

|

|

|

|

TC76 |

4 |

Vinyl |

None |

N/A |

N/A |

Yellow |

N/A |

|

|

|

|

TC158 |

7 |

Vinyl |

Rubber |

17 |

16 |

Yellow |

Up to 194°F |

|

|

|

|

TC790 |

4 |

Vinyl |

None |

N/A |

N/A |

Black |

N/A |

|

|

|

TAPECASE.COM [email protected] 847-299-7880 847-299-7804 (FAX)